12 june 2024

News

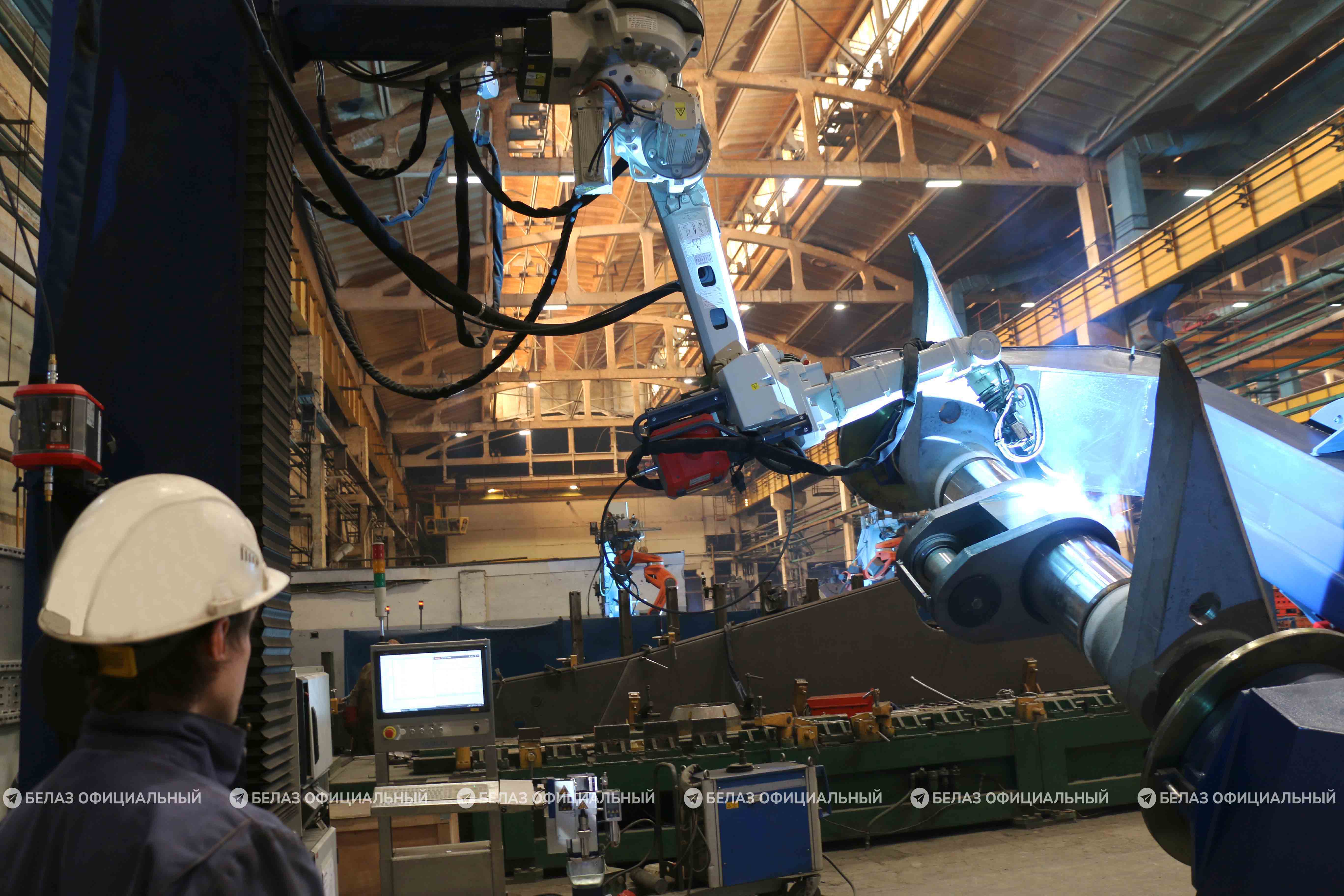

Modern welding technologies and robotic technological complexes (RTC) are being introduced into the production shops of the enterprise. Thus, robotic welding of crossbars of dump truck frames in the welding shop has reached 90% of the total volume of welding of such components.

Today, the workshop is at the final stage of commissioning and testing of the software for the latest RTC welding of frame cross members with programmable preheating processes.

Innovative welding technologies are designed to ensure an increase in labor productivity in the manufacture of frame elements, improve the quality of welded joints, and reduce the labor intensity of operations.

Among the key tasks of the RTC operator there are now only a few functions - installation and removal of components, plus startup and general control of the operation of the complex, and the control program of the robotic complex is responsible for everything else.

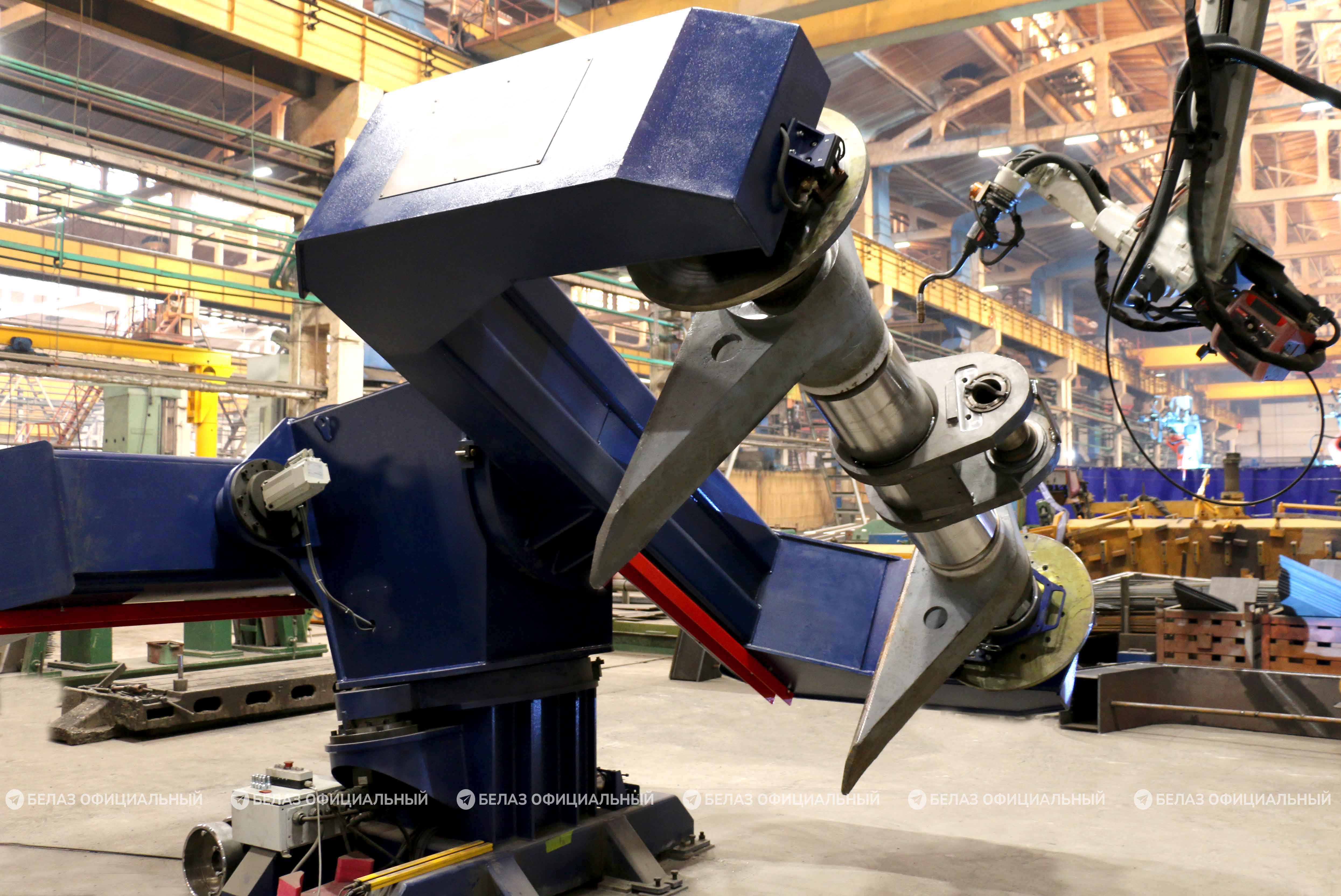

The RTC for welding frame cross members includes an industrial robotic manipulator, a rotary five-axis positioner with two workstations and advanced welding equipment. The complex is designed for welding products with maximum dimensions of 2.4 by 2 meters and weighing up to 3 tons with the possibility of pre-heating in automatic mode before welding.

In general, the welding shop currently operates more than two dozen robotic complexes, which include more than 40 robots. With the commissioning of the new robotic complex, the process of automation of welding of frame cross members will amount to approximately 90% of the total volume of welding of units.

news: