25 june 2024

News

BELAZ maintains a high pace of implementation of a large-scale investment program for modernization of production, introducing the latest technologies and high-performance equipment in the workshops of the enterprise.

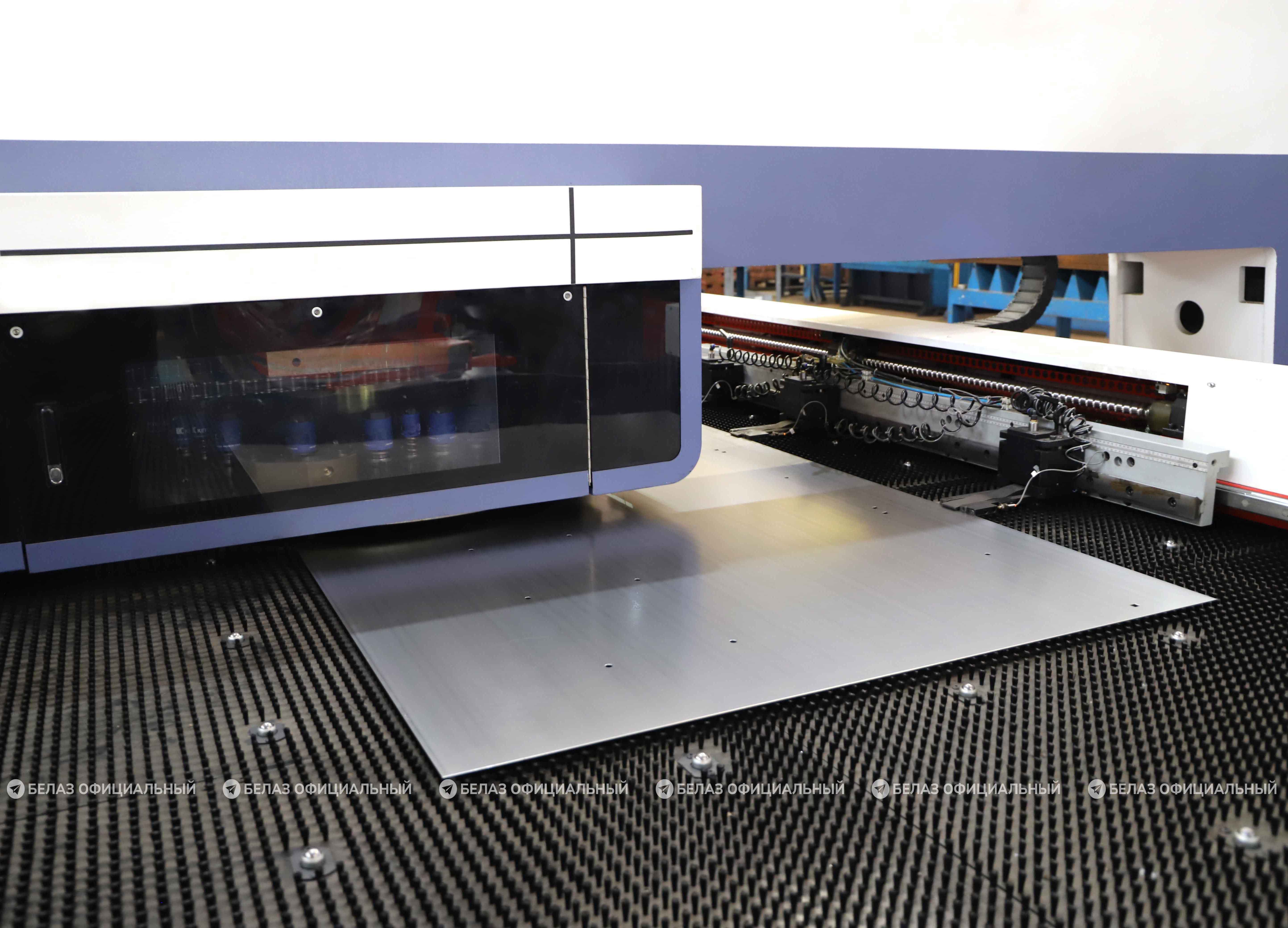

The machine park of the press workshop was supplemented with a modern coordinate-punching press with a program control system. The new equipment is designed to automatically perform punching and forming operations with high productivity, accuracy and surface quality of sheet metal parts. Such products with a large number of technological holes are used in the tail of quarry equipment - these are gratings, lining, etc.

The high-speed execution of operations on such modern equipment makes the process of serial hole production more productive and cost-effective. Thus, in comparison with laser cutting, individual parts are produced on a jig press three times faster.

In addition, the ability to use large rolled sheets reduces the number of necessary welding and other technological tasks, reducing the final cost of the part and increasing its quality.

news: