6 december 2024

News

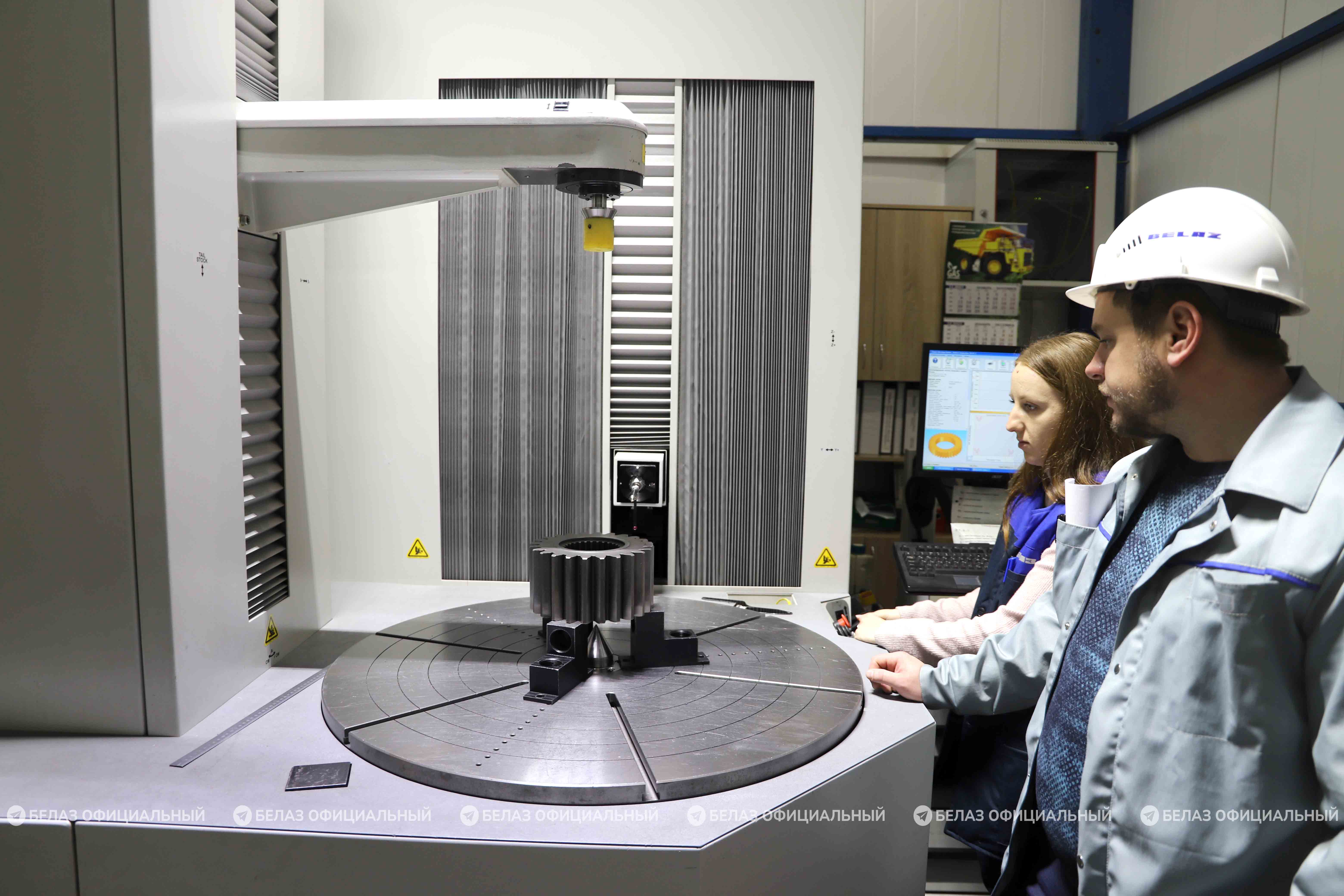

In solving the strategic task of improving the quality of manufactured products and following global trends in the field of product quality control, BELAZ continues to invest in equipping its workshops with high-tech measuring equipment.

Six coordinate measuring machines (CMM) currently monitor compliance with high quality standards of geometrically complex parts and units of BELAZ dump trucks. Two more specialized high-precision machines, which have already arrived at the enterprise, will be introduced soon.

– CMM is a universal equipment for effective control of almost all standardized parameters of precision of manufacturing of products, both at the stage of their development and in the mode of serial production of parts of quarry equipment. For us, “quality” is not just a word, but a competitive advantage embedded in each BELAZ, – notes the head of the bureau of geometric and physical measurements of the quality control department of BELAZ Evgeny Rusak.

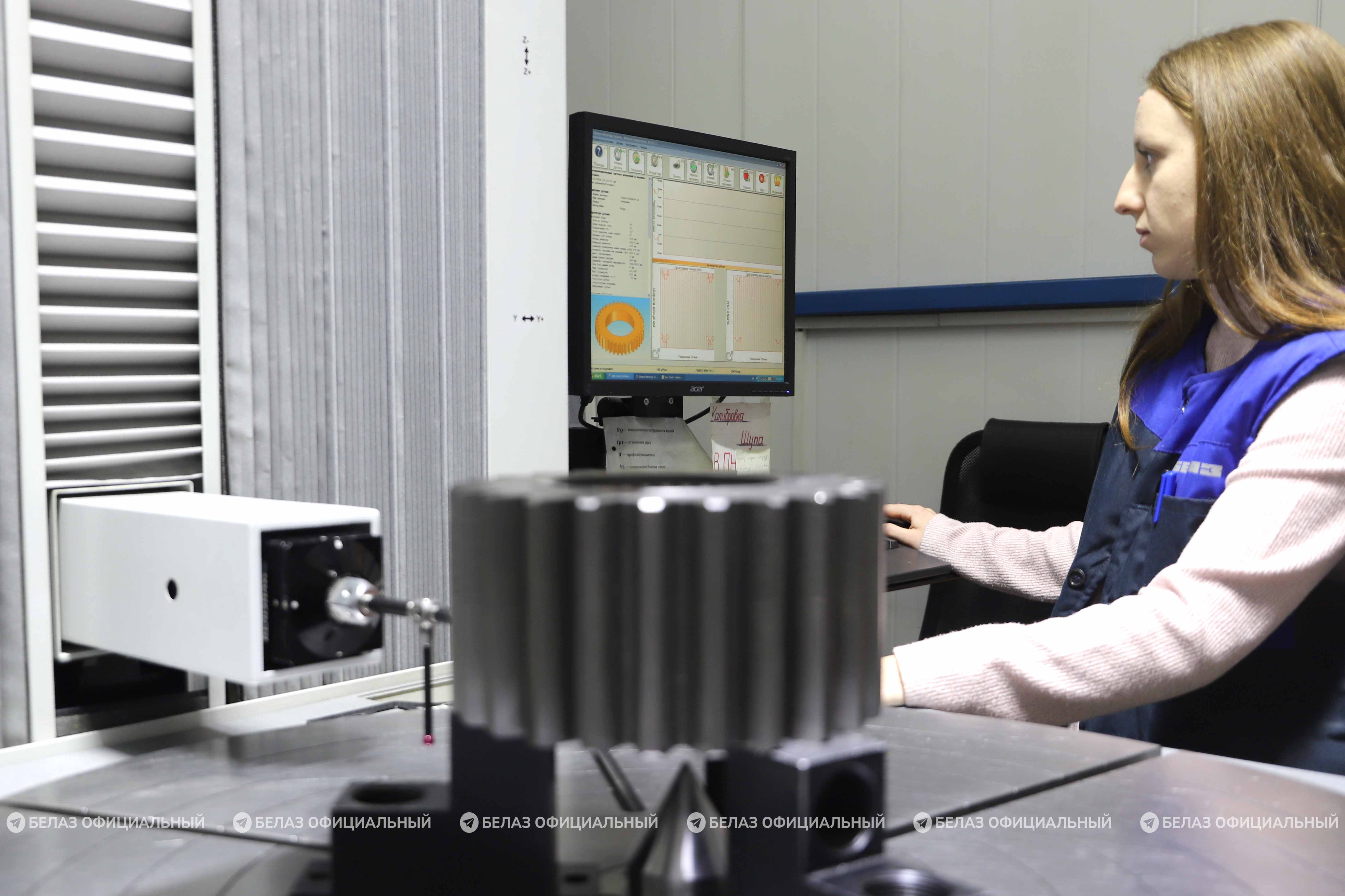

The main advantage of modern CMMs is the ability to fully automate high-precision measurement processes, as well as process and save the results of the measurements taken.

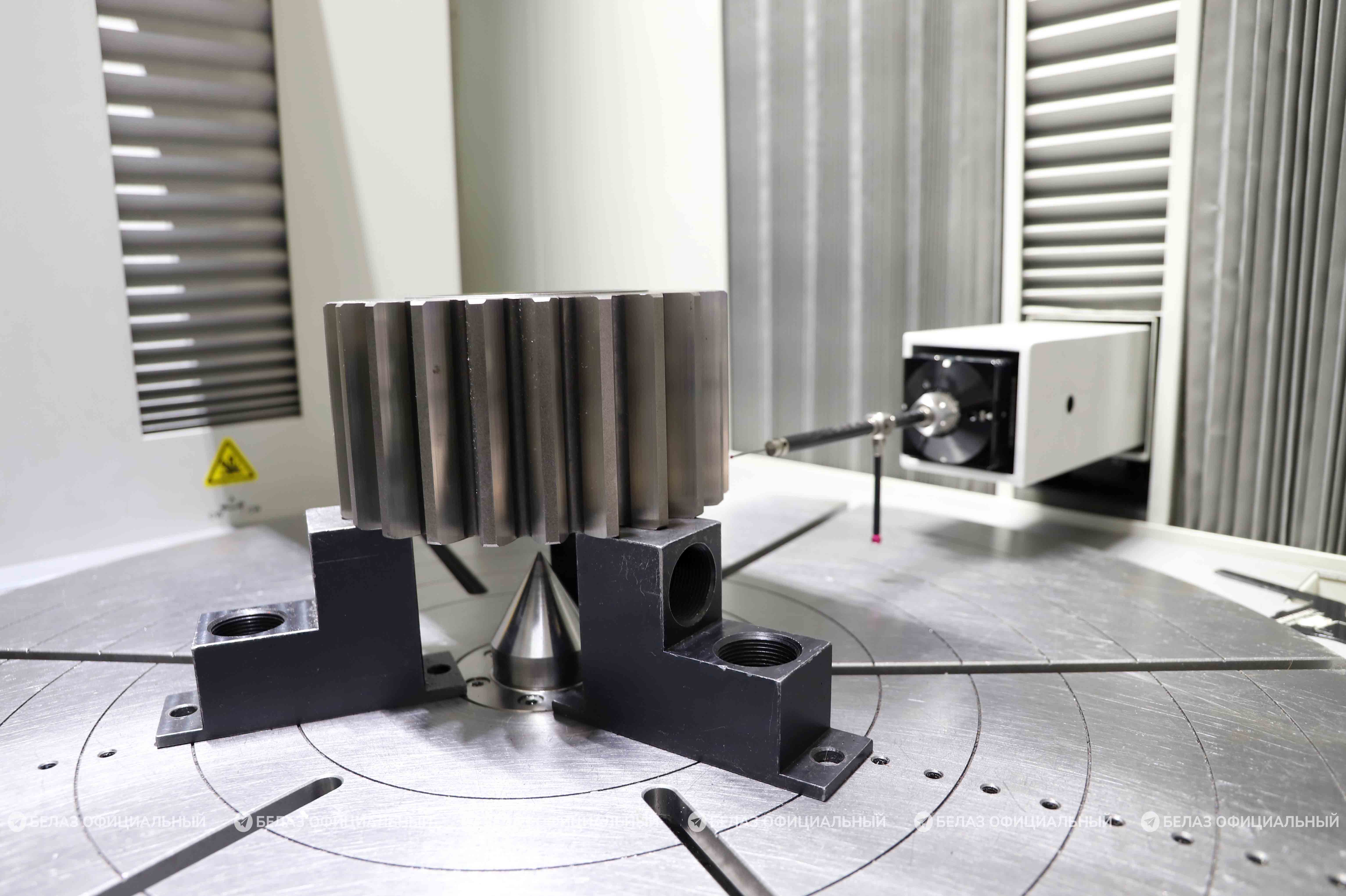

The coordinate measurement method allows these modern programmable machines to precisely control the conformity of the design documentation of the geometric parameters and characteristics of the surfaces of products - parallelism, coaxiality, angles, perpendicularity, etc. Moreover, to do this quickly and with the highest precision, which is necessary for the mating of parts (for example, gears) in the most critical units of mining dump trucks.

CMMs operate in different BELAZ workshops and are adapted to specific conditions of the technological process and types of products, and therefore differ from each other in technical characteristics, software and technologies. In the welding workshop, for example, a mobile CMM is used, measuring parts in an angular spherical coordinate system.

The largest of the machines operates in the program machine shop – a three-coordinate portal-type CMM used for automatic control of large-sized parts of complex spatial shape, such as motor-wheel reducer’s housings, rear and front wheel hubs, half-frames, etc. In terms of its capabilities, this machine surpasses its analogues available in Belarus and even in the CIS countries.

news: