KEY SPECIFICATIONS:

Engine power, kW

265 — 309

Operating weight, kg

22 600

Body volume, m³

15.1 — 24.7

Payload capacity, mt

30

0%

KEY SPECIFICATIONS:

Engine power, kW

265 — 309

Operating weight, kg

22 600

Body volume, m³

15.1 — 24.7

Payload capacity, mt

30

General Specification

Application

BELAZ-7540А mining dump trucks are designed for transportation of loosened rock in severe mining conditions of deep open pit mines on haul roads under various climatic operating conditions. These trucks can be used in construction of large industrial and hydraulic structures, highway systems, as well as in manufacturing departments of the processors. Depending on the specific weight of the transported cargo, the greatest efficiency is achieved when operating with excavators and loaders with buckets of the following capacity: 4-8 m³.

Payload capacity

30

33 short tons

Engine power, kW (hp)

309 (420)

Transmission

hydromechanical

Gear range

5+2

Torque, N*m (rpm)

1491 / 1600

Specific fuel consumption @ rated power, g/kW*h

228

Tires

18.00-25; 18.00R25

Suspension

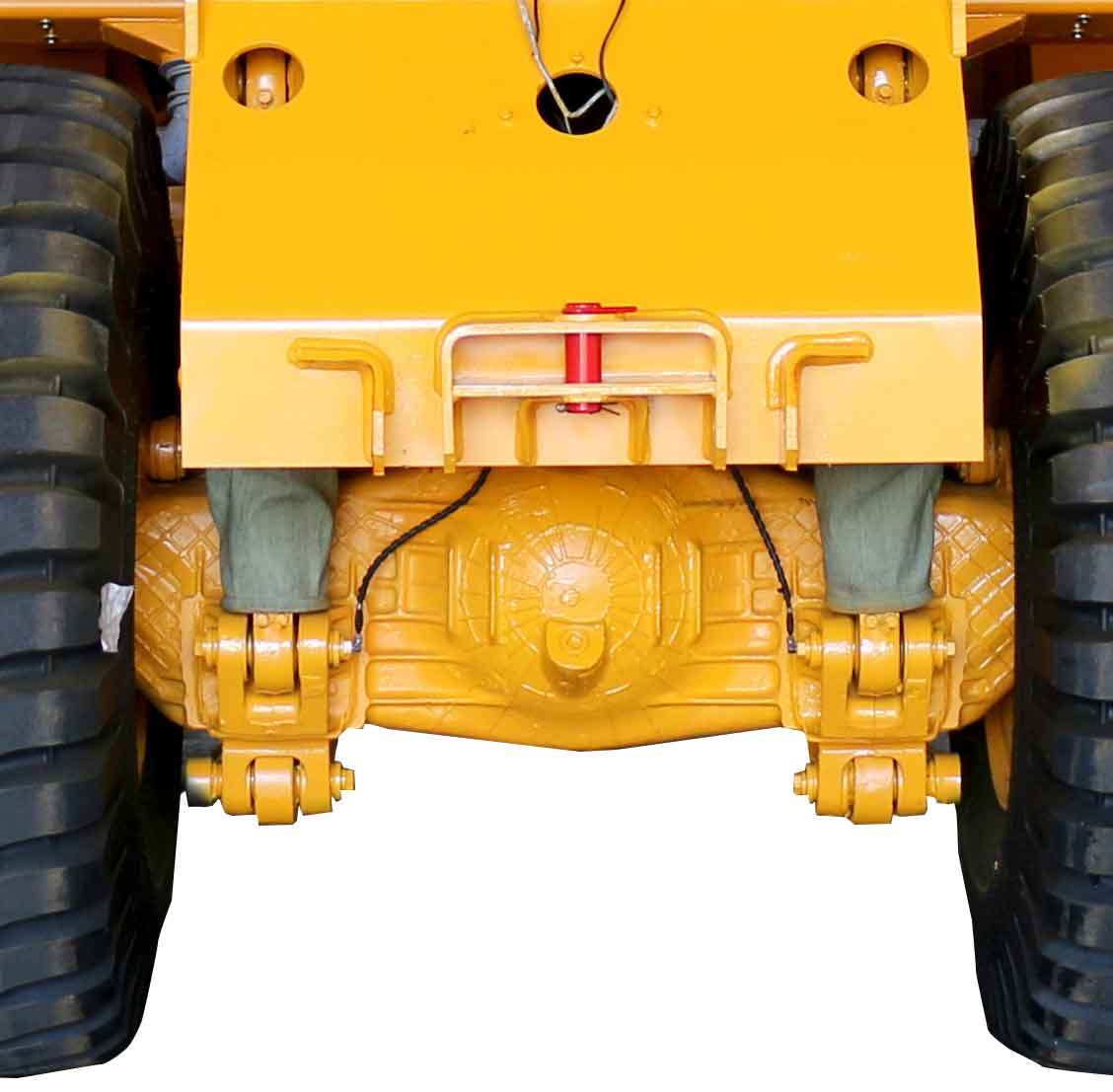

Conventional for front axle and driving axle, with longitudinal and transverse rods. Air-hydraulic (oil and nitrogen) cylinders with built-in hydraulic shock absorbers; two cylinders per front axle and rear axle.

Driving axle

Mechanical with single-stage final drive with bevel gears with circle-arc tooth, straight bevel gear differential with four pinions, planetary hub drives with spur pinions.

Max speed, km/h

50

Turning radius, m

8.7

Brake System

Front wheels

shoe brakes

Rear wheels

shoe brakes

Parking brake

shoe brake

Auxiliary brake

hydrodynamic retarder

Body volume, m³

Struck

15.1; 17.8

Heaped 2:1

19.2; 21.7

Weight

Operational weight, kg

22 600 (standard equipment package)

Gross weight, kg

52 600

Terms and Model of Financing

Contractor Operations

Operating and Financial Leasing

Renting

General Specification

Application

BELAZ-7540B mining dump trucks are designed for transportation of loosened rock in severe mining conditions of deep open pit mines on haul roads under various climatic operating conditions. These trucks can be used in construction of large industrial and hydraulic structures, highway systems, as well as in manufacturing departments of the processors. Depending on the specific weight of the transported cargo, the greatest efficiency is achieved when operating with excavators and loaders with buckets of the following capacity: 4-8 m³.

Payload capacity

30

33 short tons

Engine power, kW (hp)

265 (360)

Transmission

hydromechanical

Gear range

3+1

Torque, N*m (rpm)

1275 / 1600

Specific fuel consumption @ rated power, g/kW*h

230

Tires

18.00-25; 18.00R25

Suspension

Conventional for front axle and driving axle, with longitudinal and transverse rods. Air-hydraulic (oil and nitrogen) cylinders with built-in hydraulic shock absorbers; two cylinders per front axle and rear axle.

Driving axle

Mechanical with single-stage final drive with bevel gears with circle-arc tooth, straight bevel gear differential with four pinions, planetary hub drives with spur pinions.

Max speed, km/h

50

Turning radius, m

8.7

Brake System

Front wheels

shoe brakes

Rear wheels

shoe brakes

Parking brake

shoe brake

Auxiliary brake

hydrodynamic retarder

Body volume, m³

Struck

15.1

Heaped 2:1

19.2

Weight

Operational weight, kg

22 600 (standard equipment package)

Gross weight, kg

52 600

Terms and Model of Financing

Contractor Operations

Operating and Financial Leasing

Renting

General Specification

Application

BELAZ-7540E mining dump trucks are designed for transportation of loosened rock in severe mining conditions of deep open pit mines on haul roads under various climatic operating conditions. These trucks can be used in construction of large industrial and hydraulic structures, highway systems, as well as in manufacturing departments of the processors. Depending on the specific weight of the transported cargo, the greatest efficiency is achieved when operating with excavators and loaders with buckets of the following capacity: 4-8 m³.

Payload capacity

30

33 short tons

Engine power, kW (hp)

265 (360)

Transmission

hydromechanical

Gear range

3+1

Torque, N*m (rpm)

1275 / 1600

Specific fuel consumption @ rated power, g/kW*h

230

Tires

18.00-25; 18.00R25

Suspension

Conventional for front axle and driving axle, with longitudinal and transverse rods. Air-hydraulic (oil and nitrogen) cylinders with built-in hydraulic shock absorbers; two cylinders per front axle and rear axle.

Driving axle

Mechanical with single-stage final drive with bevel gears with circle-arc tooth, straight bevel gear differential with four pinions, planetary hub drives with spur pinions.

Max speed, km/h

50

Turning radius, m

8.7

Brake System

Front wheels

shoe brakes

Rear wheels

shoe brakes

Parking brake

shoe brake

Auxiliary brake

hydrodynamic retarder

Body volume, m³

Struck

24.7

Heaped 2:1

28.2

Weight

Operational weight, kg

22 600 (standard equipment package)

Gross weight, kg

52 600

Terms and Model of Financing

Contractor Operations

Operating and Financial Leasing

Renting

General Specification

Application

BELAZ-7540T mining dump trucks are designed for transportation of loosened rock in severe mining conditions of deep open pit mines on haul roads under various climatic operating conditions. These trucks can be used in construction of large industrial and hydraulic structures, highway systems, as well as in manufacturing departments of the processors. Depending on the specific weight of the transported cargo, the greatest efficiency is achieved when operating with excavators and loaders with buckets of the following capacity: 4-8 m³.

Payload capacity

30

Engine power, kW (hp)

353 (480)

Transmission

hydromechanical

Gear range

5+2

Torque, N*m (rpm)

1800

Specific fuel consumption @ rated power, g/kW*h

198

Tires

18.00R25

Suspension

Conventional for front axle and driving axle, with longitudinal and transverse rods. Air-hydraulic (oil and nitrogen) cylinders with built-in hydraulic shock absorbers; two cylinders per front axle and rear axle.

Driving axle

Mechanical with single-stage final drive with bevel gears with circle-arc tooth, straight bevel gear differential with four pinions, planetary hub drives with spur pinions.

Max speed, km/h

50

Turning radius, m

8.7

Dimensions, mm

* Overall dimensions are indicated for the basic configuration of the dump truck

7410*4170*4560

Brake System

Front wheels

shoe brakes

Rear wheels

shoe brakes

Parking brake

shoe brake

Auxiliary brake

hydrodynamic retarder

Body volume, m³

Struck

15.1

Heaped 2:1

19.2

Terms and Model of Financing

Contractor Operations

Operating and Financial Leasing

Renting

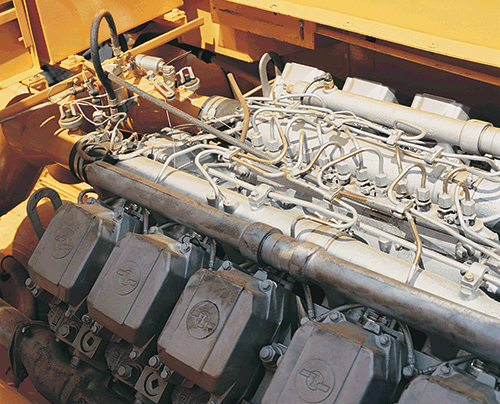

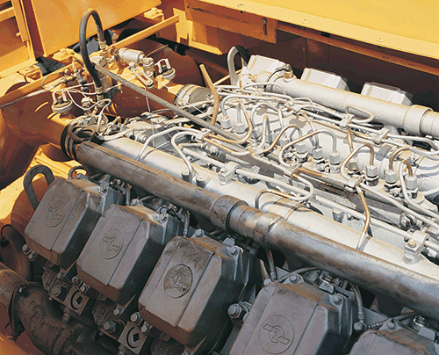

Diesel engines provide high specific power and high speed of dump truck when driving uphill, as well as high fuel efficiency.

To facilitate starting of the engine at low temperatures mining dump trucks are equipped with engine liquid preheater, which provides heating of diesel fuel and coolant at starting of the engine.

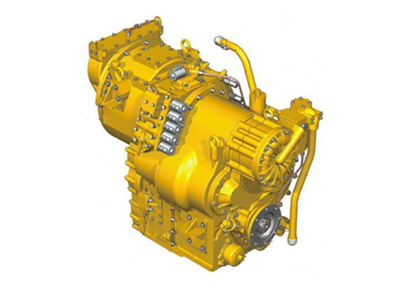

Hydromechanical transmission allows to choose the optimal traction and speed mode of motion which makes it easy to drive the vehicle and ensures safety.

Torque converter reduces the dynamic loads in the transmission and provides stable operation of the engine during changes of the loads.

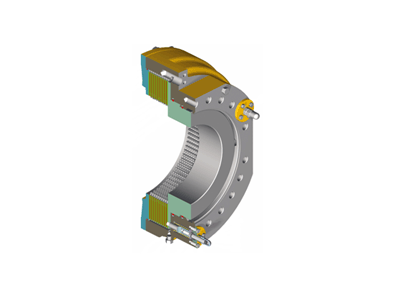

Pneumohydraulic suspension of mining dump truck with integrated hydraulic shock absorber in combination with the conventional system of the guiding apparatus provides high smoothness, performance, technical speed, lateral roll resistance and durability of dump truck components and comfortable working conditions for the operator.

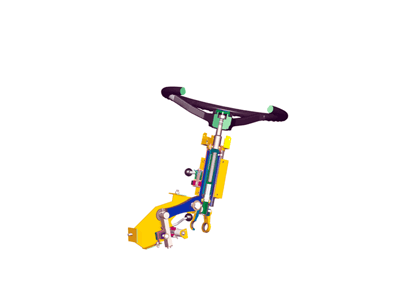

High performance, reliability and efficiency of BELAZ-7540 series dump trucks is provided by application of highly efficient engines by leading engine manufacturers, up-to-date hydromechanical transmissions, efficient hydraulic steering systems and body hoist.

The manufactured equipment is equipped with additional units and systems that expand the functionality and improve operational attractiveness. There are standard and optional equipment sets. The set of equipment depends on climatic zone of operation: it can be northern or tropical.

Fire-fighting system with remote actuation

Telemetering tire inflation control system

Centralized lubrication system

High-voltage line proximity alarm

Engine liquid preheater

Clear comparison