KEY SPECIFICATIONS:

Engine power, kW

522 (700)— 565 (757)

Operating weight, kg

35 100

Body volume, m³

22.3 — 51.5

Payload capacity, mt

55 — 60

KEY SPECIFICATIONS:

Engine power, kW

522 (700)— 565 (757)

Operating weight, kg

35 100

Body volume, m³

22.3 — 51.5

Payload capacity, mt

55 — 60

General Specification

Application

BELAZ-7555A mining dump trucks are designed for transportation of loosened rock in severe mining conditions of deep open pit mines on haul roads under various climatic operating conditions. These trucks can be used in construction of large industrial and hydraulic structures, highway systems, as well as in manufacturing departments of the processors. Depending on the specific weight of the transported cargo, the greatest efficiency is achieved when operating with excavators and loaders with buckets of the following capacity: 8-12.5 m³.

Payload capacity

55

60 short tons

Engine power, kW (hp)

537 (730)

Transmission

hydromechanical

Gear range

6+1

Torque, N*m (rpm)

2744 / 1400

Specific fuel consumption @ rated power, g/kW*h

216

Tires

24.00-R35

Suspension

pneumohydraulic

Rear axle

Mechanical with single-stage final drive, bevel gear differential and planetary hub drives.

Max speed, km/h

55

Turning radius, m

9

Brake System

Front wheels

dry single-disk brakes

Rear wheels

multiple-disk oil-cooled brakes

Parking brake

shoe brake

Auxiliary brake

multiple-disk oil-cooled brakes

Body volume, m³

Struck

22.7

Heaped 2:1

32.3

Weight

Operational weight, kg

42 000 (standard equipment package)

Gross weight, kg

97 000

Terms and Model of Financing

Contractor Operations

Operating and Financial Leasing

Renting

General Specification

Application

BELAZ-7555B mining dump trucks are designed for transportation of loosened rock in severe mining conditions of deep open pit mines on haul roads under various climatic operating conditions. These trucks can be used in construction of large industrial and hydraulic structures, highway systems, as well as in manufacturing departments of the processors. Depending on the specific weight of the transported cargo, the greatest efficiency is achieved when operating with excavators and loaders with buckets of the following capacity: 8-12.5 m³.

Payload capacity

55

60 short tons

Engine power, kW (hp)

522 (700 )

Transmission

hydromechanical

Gear range

6+1

Torque, N*m (rpm)

2731 / 1400

Specific fuel consumption @ rated power, g/kW*h

209

Tires

24.00-35; 24.00R35

Suspension

Pneumohydraulic, conventional for front axle and driving axle — trailing arms with central joint.

Rear axle

Mechanical with single-stage final drive, bevel gear differential and planetary hub drives.

Max speed, km/h

55

Turning radius, m

9

Brake System

Front wheels

dry single-disk brakes

Rear wheels

multiple-disk oil-cooled brakes

Parking brake

shoe brake

Auxiliary brake

multiple-disk oil-cooled brakes

Body volume, m³

Struck

22.7; 22.3; 28; 34.6

Heaped 2:1

33.3; 35.3; 37.3; 46.1

Weight

Operational weight, kg

40 500 (standard equipment package)

Gross weight, kg

95 500

Terms and Model of Financing

Contractor Operations

Operating and Financial Leasing

Renting

General Specification

Application

BELAZ-7555D mining dump trucks are designed for transportation of loosened rock in severe mining conditions of deep open pit mines on haul roads under various climatic operating conditions. These trucks can be used in construction of large industrial and hydraulic structures, highway systems, as well as in manufacturing departments of the processors. Depending on the specific weight of the transported cargo, the greatest efficiency is achieved when operating with excavators and loaders with buckets of the following capacity: 8-12.5 m³.

Payload capacity

55

60 short tons

Engine power, kW (hp)

522 (700)

Transmission

hydromechanical

Gear range

6+1

Torque, N*m (rpm)

2731 / 1400

Specific fuel consumption @ rated power, g/kW*h

209

Tires

24.00-35; 24.00R35

Suspension

Pneumohydraulic, conventional for front axle and driving axle — trailing arms with central joint.

Rear axle

Mechanical with single-stage final drive, bevel gear differential and planetary hub drives.

Max speed, km/h

55

Turning radius, m

9

Brake System

Front wheels

dry single-disk brakes

Rear wheels

multiple-disk oil-cooled brakes

Parking brake

shoe brake

Auxiliary brake

multiple-disk oil-cooled brakes

Body volume, m³

Struck

50

Heaped 2:1

57.9

Weight

Operational weight, kg

41 500 (standard equipment package)

Gross weight, kg

96 500

Terms and Model of Financing

Contractor Operations

Operating and Financial Leasing

Renting

General Specification

Application

BELAZ-7555H mining dump trucks are designed for transportation of loosened rock in severe mining conditions of deep open pit mines on haul roads under various climatic operating conditions. These trucks can be used in construction of large industrial and hydraulic structures, highway systems, as well as in manufacturing departments of the processors. Depending on the specific weight of the transported cargo, the greatest efficiency is achieved when operating with excavators and loaders with buckets of the following capacity: 8-12.5 m³.

Payload capacity

55

60 short tons

Engine power, kW (hp)

522 (700)

Transmission

hydromechanical

Gear range

6+1

Torque, N*m (rpm)

2731 / 1400

Specific fuel consumption @ rated power, g/kW*h

209

Tires

24.00-35 НС 42 / 24.00R35

Suspension

Pneumohydraulic, conventional for front axle and driving axle — trailing arms with central joint.

Rear axle

Mechanical with single-stage final drive, bevel gear differential and planetary hub drives.

Max speed, km/h

55

Turning radius, m

9

Brake System

Front wheels

dry single-disk brakes

Rear wheels

multiple-disk oil-cooled brakes

Parking brake

shoe brake

Auxiliary brake

multiple-disk oil-cooled brakes

Body volume, m³

Struck

22.7; 22.3; 28.0

Heaped 2:1

33.3; 35.3; 37.3

Weight

Operational weight, kg

41 500 (standard equipment package)

Gross weight, kg

96 500

Terms and Model of Financing

Contractor Operations

Operating and Financial Leasing

Renting

General Specification

Application

BELAZ-7555I mining dump trucks are designed for transportation of loosened rock in severe mining conditions of deep open pit mines on haul roads under various climatic operating conditions. These trucks can be used in construction of large industrial and hydraulic structures, highway systems, as well as in manufacturing departments of the processors. Depending on the specific weight of the transported cargo, the greatest efficiency is achieved when operating with excavators and loaders with buckets of the following capacity: 8-12.5 m³.

Payload capacity

60

66 short tons

Engine power, kW (hp)

565 (757 )

Transmission

hydromechanical

Gear range

6+1

Torque, N*m (rpm)

3600 / 1500

Specific fuel consumption @ rated power, g/kW*h

210

Tires

24.00R35

Suspension

Pneumohydraulic, conventional for front axle and driving axle — trailing arms with central joint.

Rear axle

Mechanical with single-stage final drive, bevel gear differential and planetary hub drives.

Max speed, km/h

55

Turning radius, m

9

Brake System

Front wheels

dry single-disk brakes

Rear wheels

multiple-disk oil-cooled brakes

Parking brake

shoe brake

Auxiliary brake

multiple-disk oil-cooled brakes

Body volume, m³

Struck

28

Heaped 2:1

37.3

Weight

Operational weight, kg

44 100 (standard equipment package)

Gross weight, kg

104 100

Terms and Model of Financing

Contractor Operations

Operating and Financial Leasing

Renting

General Specification

Application

BELAZ-7555I mining dump trucks are designed for transportation of loosened rock in severe mining conditions of deep open pit mines on haul roads under various climatic operating conditions. These trucks can be used in construction of large industrial and hydraulic structures, highway systems, as well as in manufacturing departments of the processors. Depending on the specific weight of the transported cargo, the greatest efficiency is achieved when operating with excavators and loaders with buckets of the following capacity: 8-12.5 m³.

Payload capacity

55

Engine power, kW (hp)

522 (700)

Transmission

hydromechanical

Gear range

6+1

Torque, N*m (rpm)

4630 (1300)

Specific fuel consumption @ rated power, g/kW*h

210

Tires

24.00-35; 24.00R35

Suspension

Pneumohydraulic, conventional for front axle and driving axle — trailing arms with central joint.

Rear axle

Mechanical with single-stage final drive, bevel gear differential and planetary hub drives.

Max speed, km/h

55

Turning radius, m

9

Dimensions, mm

* Overall dimensions are indicated for the basic configuration of the dump truck

8890*5690*4860

Brake System

Front wheels

dry single-disk brakes

Rear wheels

multiple-disk oil-cooled brakes

Parking brake

shoe brake

Auxiliary brake

multiple-disk oil-cooled brakes

Body volume, m³

Struck

22.7

Heaped 2:1

32.3

Weight

Operational weight, kg

43000

Gross weight, kg

98000

Terms and Model of Financing

Contractor Operations

Operating and Financial Leasing

Renting

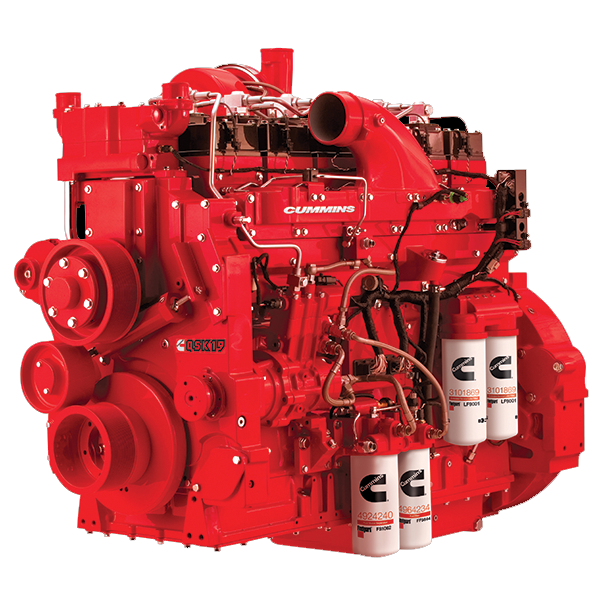

Diesel engines with electronic control and central switching-off impeller of cooling system provide high specific power and consequently high speed of dump truck when driving uphill, as well as high fuel efficiency.

To facilitate starting of the engine at low temperatures mining dump trucks are equipped with engine liquid preheater, which provides heating of diesel fuel and coolant at starting of the engine, which significantly increases engine service life and ensures reliable operation of the system in various climatic zones, including the Far North.

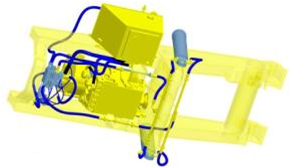

Hydromechanical transmission with six forward and one reverse gear allows to choose the optimal traction and speed mode of motion which makes it easy to drive the vehicle and ensures safety.

Torque converter reduces the dynamic loads in the transmission and provides stable operation of the engine during changes of the loads.

Automatic control system of hydromechanical transmission improves performance of dump truck, increases service life and reliability by maintaining the optimum operating modes.

Due to increased efficiency of the multiple-disk oil-cooled brakes and forced cooling system the average technical speed when driving on a slope is increased by 10...20%.

The response time of the multiple-disk oil-cooled brakes in the retarder mode is reduced by 4–5 times in comparison with the hydrodynamic retarder.

The nominal braking torque of the service and auxiliary brakes is increased.

Application of the multiple-disk oil-cooled brakes increases reliability of equipment and safety of operation.

Pneumohydraulic suspension of mining dump truck with integrated hydraulic shock absorber in combination with the conventional system of the guiding apparatus provides high smoothness, performance, technical speed, lateral roll resistance and durability of dump truck components and comfortable working conditions for the operator.

The performance, reliability and operational attractiveness of BELAZ-7555 series dump trucks is ensured by the use of highly efficient, economical engines of leading engine-manufacturing companies, modern hydromechanical transmission, efficient suspension, comfortable cab, powerful and reliable hydraulic system.

The manufactured equipment is equipped with additional units and systems that expand the functionality and improve operational attractiveness. There are standard and optional equipment sets. The set of equipment depends on climatic zone of operation: it can be northern or tropical.

Heating and air conditioning unit

Rock ejectors

Fire-fighting system with remote actuation

Loading and fuel control system

Telemetering tire inflation control system

Centralized lubrication system

High-voltage line proximity alarm

Body bottom plate lining

Wiggins fast fueling system

Clear comparison