Engine power, kW (hp)

783 (1050)

Operational weight, kg

107 800

Bucket capacity, m³

11

Engine power, kW (hp)

783 (1050)

Operational weight, kg

107 800

Bucket capacity, m³

11

General Specification

Application

Designed for mechanization of loading (crushed stones, sand, gravel, rock, soil, etc) of mining dump trucks with payload capacity 90-136t, railway cars, dump cars and other vehicles at open cast mines, railway stations and other facilities.

Payload capacity

22mt

Engine power, kW (hp)

783 (1050)

Transmission

Electromechanical AC

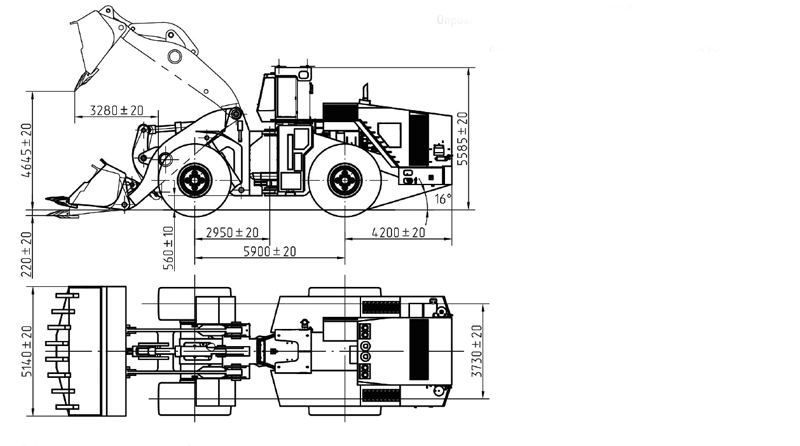

Dimensions, mm

* Overall dimensions are indicated for the basic configuration of the dump truck

Length - 15350 mm, Width - 5140 mm, Height - 5600 mm

General Specification

Operational weight, kg

107 800

Gross weight, kg

129 800

Tires

45/65R45

Max speed, km/h

24

Wheel formula

4х4

Frame

Articulated

Bucket volume, m³

struck - 6.3; 9.5; 15; rated - 8; 11.5; 18;

Terms and Model of Financing

Contractor Operations

Operating and Financial Leasing

Renting

The loader is equipped with an electromechanical transmission (EMT) of alternating current produced by the St. Petersburg "Electrosila" plant (branch of OJSC "Power Machines"), which increases the productivity of the loader and reduces the cost and time of maintenance. The drive is designed using the latest advances in the industry.

The application of electromechanical transmission allows to exclude structurally complex and expensive to maintain gearbox and torque converter. Traction motors provide high torque and do not require maintenance. Traction alternator maintenance is also minimized. The torque on each wheel is separately regulated and electronically controlled, which reduces tire wear and increases service life.

The modern integrated hydraulic system, designed to ensure the reliability and high operational dynamics of BELAZ-78250 loader, is completely controlled by a computer. Loader steering and working equipment are controlled by electric joysticks, which, in turn, control proportional valves of the hydraulic control valve group.

This solution made it possible to exclude the feeding of hydraulic hoses inside the cab. The control of working equipment is integrated with an automatic positioning system that allows in automatic mode with a minimum number of operations for the driver to raise the bucket to preset heights and return it to its working position, lowering it to the cutting position on the ground, which significantly increases the operator’s convenience and efficiency.

The loader is equipped with weighing system, which data is displayed on the electronic panel along with other data on the operation of the loader and its systems.

Today, the loader can use 3 sizes of buckets: standard — 11.5 m³, for heavy rocks — 8 m³ and coal — 18 m³. Buckets are welded from stainless steel sheet metal and designed to work on abrasive and rock formations. Sufficiently large unloading angle — 45 degrees — helps to reduce the sticking of the load to the bottom and walls of the bucket. Additionally, it is possible to knock out frozen ground by hitting the ground when turning the bucket to unloading angle of more than 70 degrees. Due to the increased size, loading height and bucket volume, the range of servicable dump trucks is expanded — new front-end loader can load mining dump trucks with payload capacity of 90 and 130 metric tons. BELAZ-78250 front-end loader can be equipped with remote control system that allows loading dump trucks in the mine from remote workstation.

Clear comparison