KEY SPECIFICATIONS:

Engine power, kW

895 — 1400

Operational weight, kg

100 100 — 109 500

Body volume, m³

40 — 103.8

Payload capacity, mt

110 — 140

KEY SPECIFICATIONS:

Engine power, kW

895 — 1400

Operational weight, kg

100 100 — 109 500

Body volume, m³

40 — 103.8

Payload capacity, mt

110 — 140

General Specification

Application

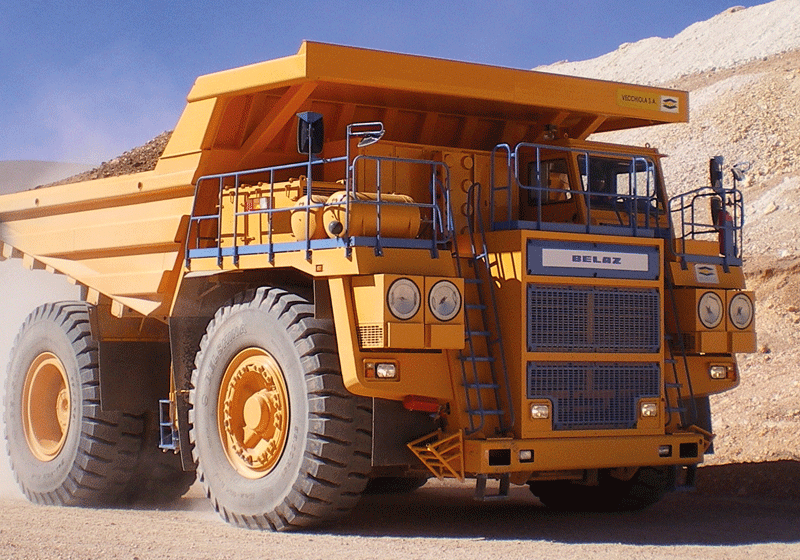

BELAZ-75131 mining dump trucks are designed for transportation of loosened rock in severe mining conditions of deep open pit mines on haul roads under various climatic operating conditions. These trucks can be used in construction of large industrial and hydraulic structures, highway systems, as well as in manufacturing departments of the processors. Depending on the specific weight of the transported cargo, the greatest efficiency is achieved when operating with excavators and loaders with buckets of the following capacity: 12-20 m³.

Payload capacity

130-140 mt

143-150 st

Engine power, kW (hp)

1194 (1600)

Transmission

AC/DC electromechanical

Dimensions, mm

* Overall dimensions are indicated for the basic configuration of the dump truck

Standard body:

Length - 11 500 mm

Width - 6 400 mm

Height - 5900 mm

Coal body:

Length - 12 050 mm

Width - 7 350 mm

Height - 5 900 mm

Length - 37'9"

Width - 20'12"

Height - 19'4"

Torque, N*m (rpm)

6292 (1500)

Specific fuel consumption @ rated power, g/kW*h

208

Tires

33.00-51; 33.00R51; 36/90-51

Transmission

AC/DC

Motor-wheel reduction gear unot

planetary, double-row type

Suspension

conventional for front and driving axles — trailing arms with central hinge

Traction electric motor

EDP-600; EK-590; TED-6;ED-136;EK-420A

Traction alternator

GSN-500; GST-1; SGT-1000

Max speed, km/h

50

Turning radius, m

13

Brake System

Front wheels

dry disk brakes

Rear wheels

dry disk brakes

Parking brake

disk brake

Auxiliary brake

electrodynamic retarding by traction electric motors with forced air-cooling of braking resistors

Body volume, m³

Struck

40; 45.5; 50.1; 55; 59.6; 63.4; 66.6; 103.8

Heaped 2:1

67; 71.2; 75.5; 80; 84; 86.6; 89.5; 134.8

Weight

Operational weight, kg

107 100 (standard equipment package)

Gross weight, kg

237 100 - 243 100

Terms and Model of Financing

Contractor Operations

Operating and Financial Leasing

Renting

General Specification

Application

BELAZ-75135 mining dump trucks are designed for transportation of loosened rock in severe mining conditions of deep open pit mines on haul roads under various climatic operating conditions. These trucks can be used in construction of large industrial and hydraulic structures, highway systems, as well as in manufacturing departments of the processors. Depending on the specific weight of the transported cargo, the greatest efficiency is achieved when operating with excavators and loaders with buckets of the following capacity: 12-20 m³.

Payload capacity

110 - 140 mt

121 st

Engine power, kW (hp)

895 (1200 ); 940 (1260)

Transmission

AC/DC electromechanical

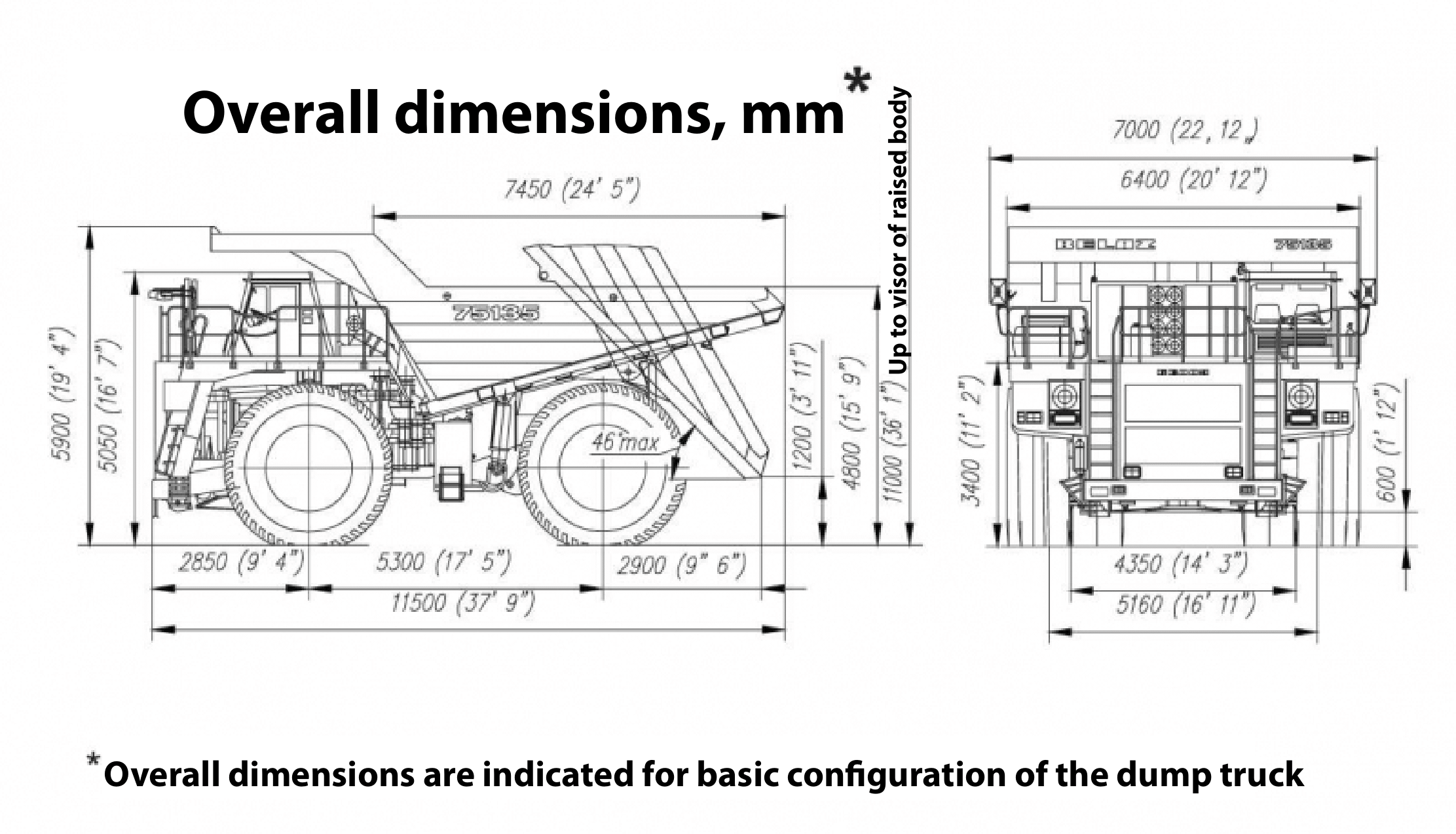

Dimensions, mm

* Overall dimensions are indicated for the basic configuration of the dump truck

Length - 11 500 mm

Width - 6 400 mm

Height - 5900 mm

Length - 37'9"

Width - 20'12"

Height - 19'4"

Torque, N*m (rpm)

4726 (1500)

Specific fuel consumption @ rated power, g/kW*h

207

Tires

33.00-51

Transmission

AC/DC

Motor-wheel reduction gear unot

planetary, double-row type

Suspension

conventional for front and driving axles — trailing arms with central hinge

Traction electric motor

EDP-600; EK-590; TED-6; ED-136; EK-420A

Traction alternator

GST-1; SGT-1000; GSN-500

Max speed, km/h

48

Turning radius, m

13

Brake System

Front wheels

dry disk brakes

Rear wheels

dry disk brakes

Parking brake

disk brake

Auxiliary brake

electrodynamic retarding by traction electric motors with forced air-cooling of braking resistors

Body volume, m³

Struck

45.5

Heaped 2:1

71.2

Weight

Operational weight, kg

100 100 (standard equipment package)

Gross weight, kg

210 100

Terms and Model of Financing

Contractor Operations

Operating and Financial Leasing

Renting

General Specification

Application

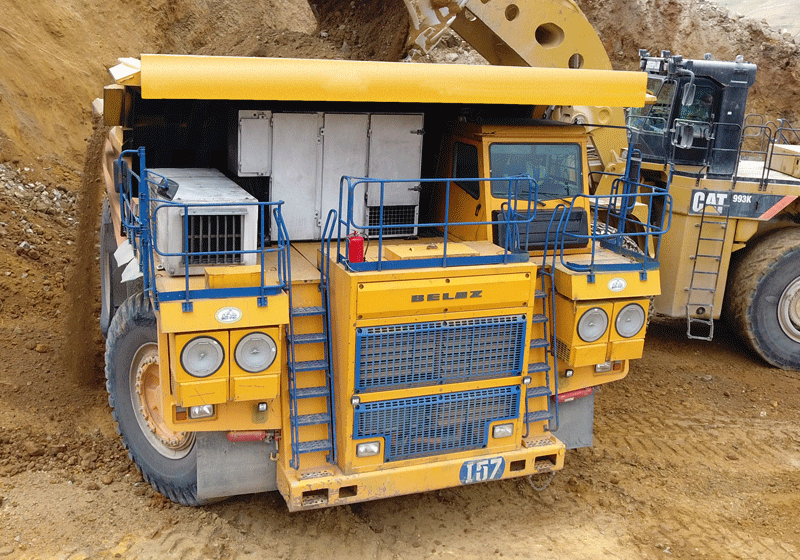

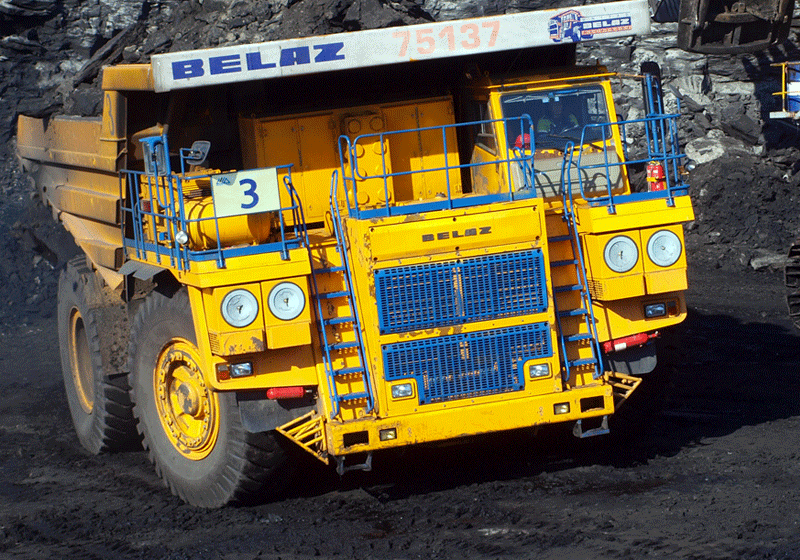

BELAZ-75137 mining dump trucks are designed for transportation of loosened rock in severe mining conditions of deep open pit mines on haul roads under various climatic operating conditions. These trucks can be used in construction of large industrial and hydraulic structures, highway systems, as well as in manufacturing departments of the processors. Depending on the specific weight of the transported cargo, the greatest efficiency is achieved when operating with excavators and loaders with buckets of the following capacity: 12-20 m³.

Payload capacity

130-140 mt

143-150 st

Engine power, kW (hp)

1194 (1600)

Transmission

AC/DC electromechanical

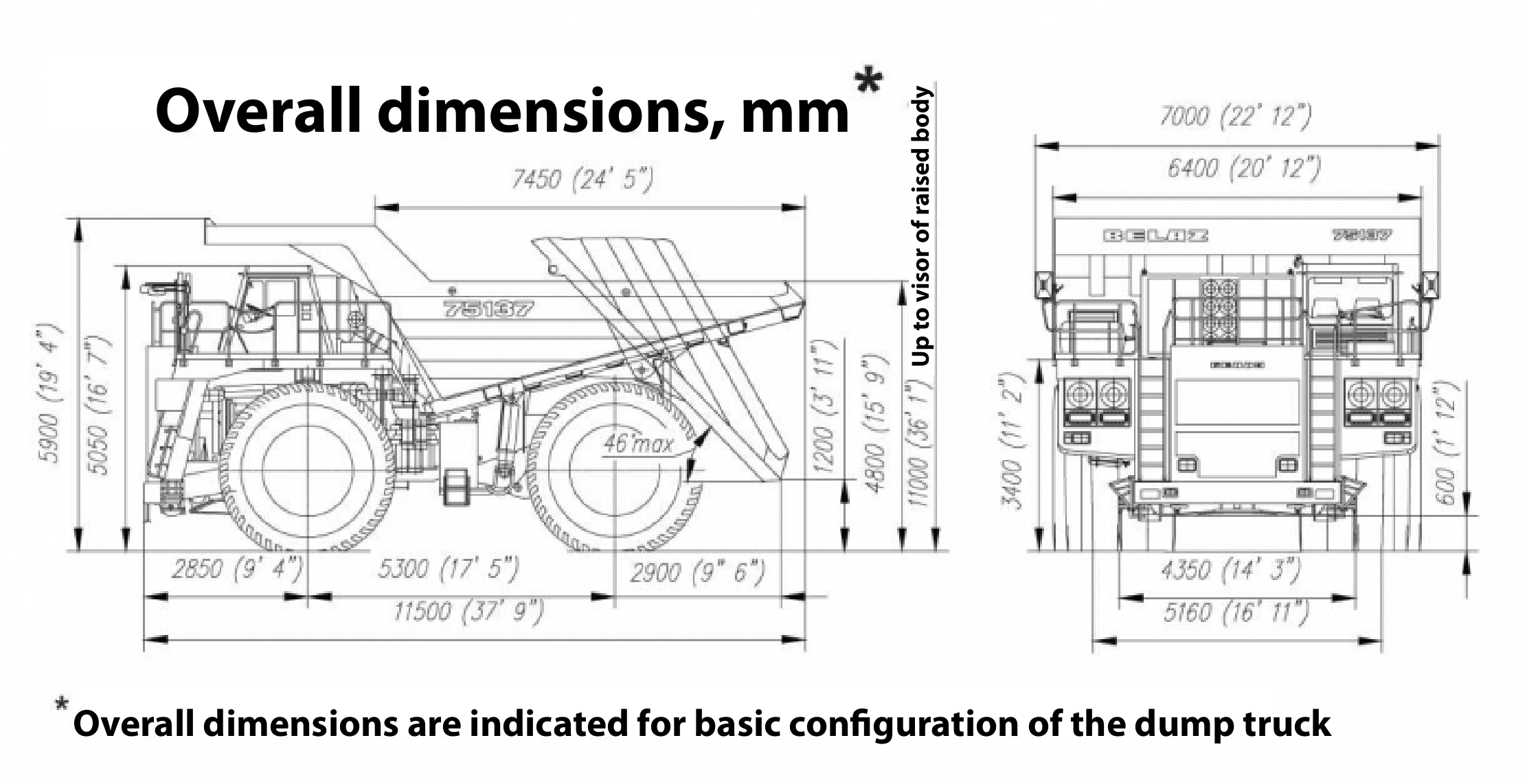

Dimensions, mm

* Overall dimensions are indicated for the basic configuration of the dump truck

Standard body:

Length - 11 500 mm

Width - 6 400 mm

Height - 5900 mm

Coal body:

Length - 12 050 mm

Width - 7 350 mm

Height - 5 900 mm

Length - 37'9"

Width - 20'12"

Height - 19'4"

Torque, N*m (rpm)

7612 (1500)

Specific fuel consumption @ rated power, g/kW*h

201

Tires

33.00-51; 33.00R51; 36/90-51

Transmission

AC/DC

Motor-wheel reduction gear unot

planetary, double-row type

Suspension

conventional for front and driving axles — trailing arms with central hinge

Traction electric motor

EDP-600; EK-590; TED-6; ED-136; EK-420A

Traction alternator

GSN-500; GST-1; SGT-1000

Max speed, km/h

48

Turning radius, m

13

Brake System

Front wheels

dry disk brakes

Rear wheels

dry disk brakes

Parking brake

disk brake

Auxiliary brake

electrodynamic retarding by traction electric motors with forced air-cooling of braking resistors

Body volume, m³

Struck

40; 45.5; 50.1; 55; 59.6; 63.4; 66.6; 103.8

Heaped 2:1

67; 71.2; 75.5; 80; 84; 86.6; 89.5; 134.8

Weight

Operational weight, kg

108 100 (standard equipment package)

Gross weight, kg

238 100 - 244 100

Terms and Model of Financing

Contractor Operations

Operating and Financial Leasing

Renting

General Specification

Application

BELAZ-75139 mining dump trucks are designed for transportation of loosened rock in severe mining conditions of deep open pit mines on haul roads under various climatic operating conditions. These trucks can be used in construction of large industrial and hydraulic structures, highway systems, as well as in manufacturing departments of the processors. Depending on the specific weight of the transported cargo, the greatest efficiency is achieved when operating with excavators and loaders with buckets of the following capacity: 12-20 m³.

Payload capacity

130-140 mt

143-150 st

Engine power, kW (hp)

1193 (1600)

Transmission

AC/AC electromechanical

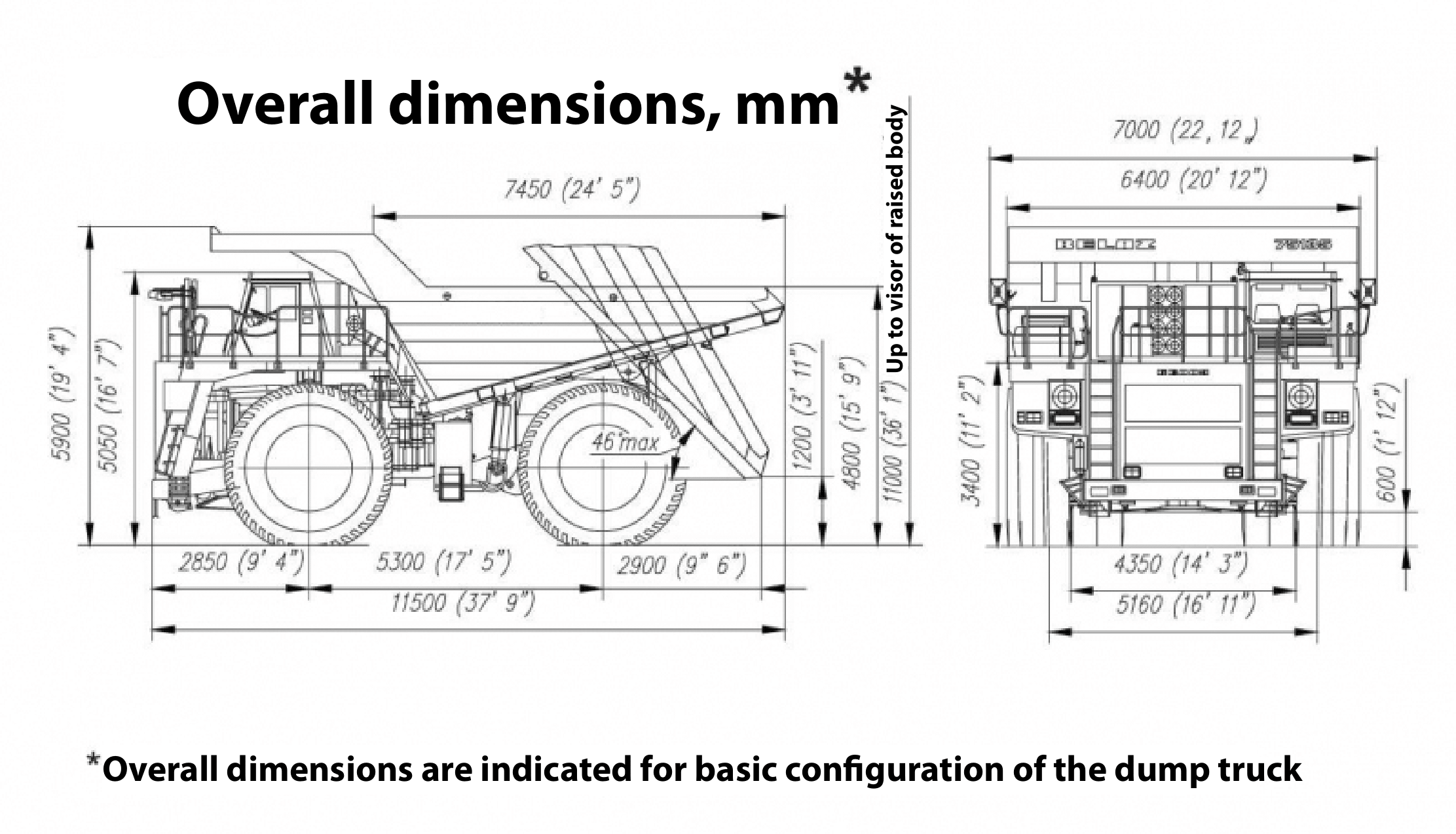

Dimensions, mm

* Overall dimensions are indicated for the basic configuration of the dump truck

Standard body:

Length - 11 500 mm

Width - 6 400 mm

Height - 5900 mm

Coal body:

Length - 12 050 mm

Width - 7 350 mm

Height - 5 900 mm

Length - 37'9"

Width - 20'12"

Height - 19'4"

Torque, N*m (rpm)

6292 (1500)

Specific fuel consumption @ rated power, g/kW*h

208

Tires

33.00-51; 33.00R51; 36/90-51

Transmission

AC/AC

Motor-wheel reduction gear unot

planetary, double-row type

Suspension

conventional for front and driving axles — trailing arms with central hinge

Traction electric motor

TAD-5

Traction alternator

GST-800

Max speed, km/h

64

Turning radius, m

13

Brake System

Front wheels

dry disk brakes

Rear wheels

dry disk brakes

Parking brake

disk brake

Auxiliary brake

electrodynamic retarding by traction electric motors with forced air-cooling of braking resistors

Body volume, m³

Struck

40; 45.5; 50.1; 55; 59.6; 63.4; 66.6; 103.8

Heaped 2:1

67; 71.2; 75.5; 80; 84; 86.6; 89.5; 134.8

Weight

Operational weight, kg

108 500 (standard equipment package)

Gross weight, kg

238 500 - 244 500

Terms and Model of Financing

Contractor Operations

Operating and Financial Leasing

Renting

General Specification

Application

BELAZ-7513D mining dump trucks are designed for transportation of loosened rock in severe mining conditions of deep open pit mines on haul roads under various climatic operating conditions. These trucks can be used in construction of large industrial and hydraulic structures, highway systems, as well as in manufacturing departments of the processors. Depending on the specific weight of the transported cargo, the greatest efficiency is achieved when operating with excavators and loaders with buckets of the following capacity: 12-20 m³.

Payload capacity

130-136 mt; If the lightweight body is installed, the payload capacity is 140 mt

Engine power, kW (hp)

1168 (1588)

Transmission

AC/DC electromechanical

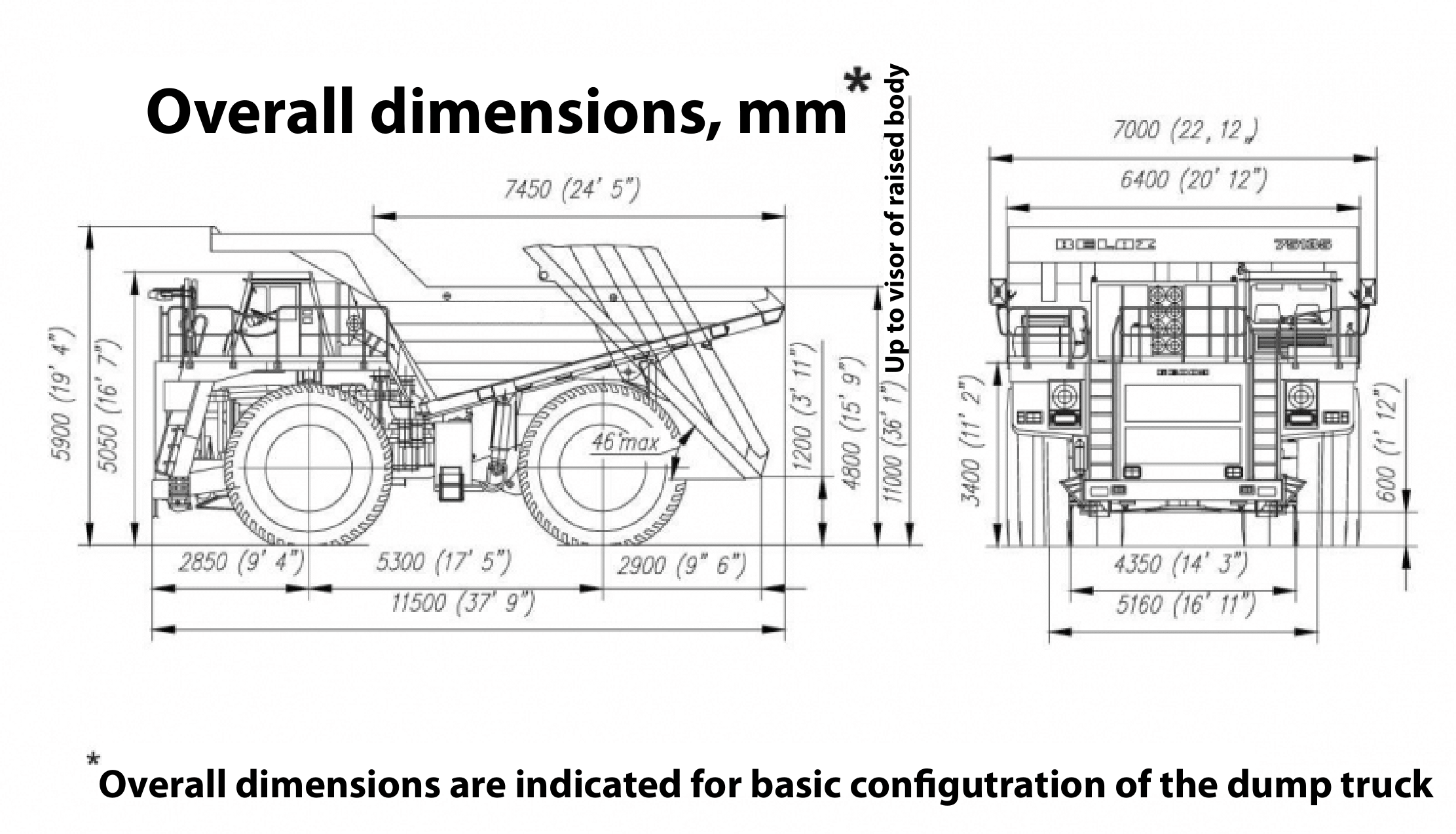

Dimensions, mm

* Overall dimensions are indicated for the basic configuration of the dump truck

Length - 11 500 mm

Width - 6 400 mm

Height - 5 900 mm

Length - 37'9"

Width - 20'12"

Height - 19'4"

Torque, N*m (rpm)

6500 / 1500

Specific fuel consumption @ rated power, g/kW*h

205

Tires

33.00-51; 33.00R51; 36/90-51

Transmission

AC/DC

Motor-wheel reduction gear unot

planetary, double-row type

Suspension

conventional for front and driving axles — trailing arms with central hinge

Traction electric motor

EK-590 D, EDP-600

Traction alternator

GSN-500, GST-1, SGT-1000

Max speed, km/h

50

Turning radius, m

13

Brake System

Front wheels

dry disk brakes

Rear wheels

dry disk brakes

Parking brake

disk brake

Auxiliary brake

electrodynamic retarding by traction electric motors with forced air-cooling of braking resistors

Body volume, m³

Struck

40.0; 45.5; 50.1; 55.0; 59.6; 63.4; 66.6; 103.8

Heaped 2:1

67.0; 71.2; 75.5; 80.0; 84.0; 86.6; 89.5; 134.8

Weight

Operational weight, kg

107 100 (standard equipment package)

Gross weight, kg

237 100 - 243 100

Terms and Model of Financing

Contractor Operations

Operating and Financial Leasing

Renting

General Specification

Application

BELAZ-7513N mining dump trucks are designed for transportation of loosened rock in severe mining conditions of deep open pit mines on haul roads under various climatic operating conditions. These trucks can be used in construction of large industrial and hydraulic structures, highway systems, as well as in manufacturing departments of the processors. Depending on the specific weight of the transported cargo, the greatest efficiency is achieved when operating with excavators and loaders with buckets of the following capacity: 12-20 m³.

Payload capacity

130-140

Engine power, kW (hp)

1193 (1600)

Transmission

AC/AC electromechanical

Dimensions, mm

* Overall dimensions are indicated for the basic configuration of the dump truck

Length - 11 500 mm

Width - 6 400 mm

Height - 5 900 mm

Length - 37'9"

Width - 20'12"

Height - 19'4"

Torque, N*m (rpm)

6292 / 1500

Specific fuel consumption @ rated power, g/kW*h

208

Tires

33.00-51; 33.00R51; 36/90-51

Transmission

AC/AC

Motor-wheel reduction gear unot

planetary, double-row type

Suspension

conventional for front and driving axles — trailing arms with central hinge

Traction electric motor

TAD-5

Traction alternator

GST-800

Max speed, km/h

60

Turning radius, m

13

Brake System

Front wheels

dry disk brakes

Rear wheels

dry disk brakes

Parking brake

disk brake

Auxiliary brake

electrodynamic retarding by traction electric motors with forced air-cooling of braking resistors

Body volume, m³

Struck

45.5; 50.1; 55.0; 59.6; 103.8

Heaped 2:1

71.2; 75.5; 80.0; 84.0; 134.8

Weight

Operational weight, kg

108 500 (standard equipment package)

Gross weight, kg

238 500 - 244 500

Terms and Model of Financing

Contractor Operations

Operating and Financial Leasing

Renting

General Specification

Application

BELAZ-7513N mining dump trucks are designed for transportation of loosened rock in severe mining conditions of deep open pit mines on haul roads under various climatic operating conditions. These trucks can be used in construction of large industrial and hydraulic structures, highway systems, as well as in manufacturing departments of the processors. Depending on the specific weight of the transported cargo, the greatest efficiency is achieved when operating with excavators and loaders with buckets of the following capacity: 12-20 m³.

Payload capacity

110

Engine power, kW (hp)

882 (1200)

Transmission

AC/AC electromechanical

Dimensions, mm

* Overall dimensions are indicated for the basic configuration of the dump truck

Length - 11 500 mm

Width - 6 400 mm

Height - 5 900 mm

Length - 37'9"

Width - 20'12"

Height - 19'4"

Torque, N*m (rpm)

6292 / 1500

Specific fuel consumption @ rated power, g/kW*h

208

Tires

33.00-51; 33.00R51; 36/90-51

Transmission

AC/AC

Motor-wheel reduction gear unot

planetary, double-row type

Suspension

conventional for front and driving axles — trailing arms with central hinge

Traction electric motor

TAD-5

Traction alternator

GST-800

Max speed, km/h

60

Turning radius, m

13

Brake System

Front wheels

dry disk brakes

Rear wheels

dry disk brakes

Parking brake

disk brake

Auxiliary brake

electrodynamic retarding by traction electric motors with forced air-cooling of braking resistors

Body volume, m³

Struck

45.5; 50.1; 55.0; 59.6; 103.8

Heaped 2:1

71.2; 75.5; 80.0; 84.0; 134.8

Terms and Model of Financing

Contractor Operations

Operating and Financial Leasing

Renting

The ratio of power and speed characteristics allows to bring the truck characteristics closer to the parameters of the ideal theoretical continuously variable transmission.

No gear shifting is required, the system provides smooth power change during movement.

Lower operating costs and greater productivity of haulage operations.

Absence of units subject to wear improves performance and reduces the cost of operation.

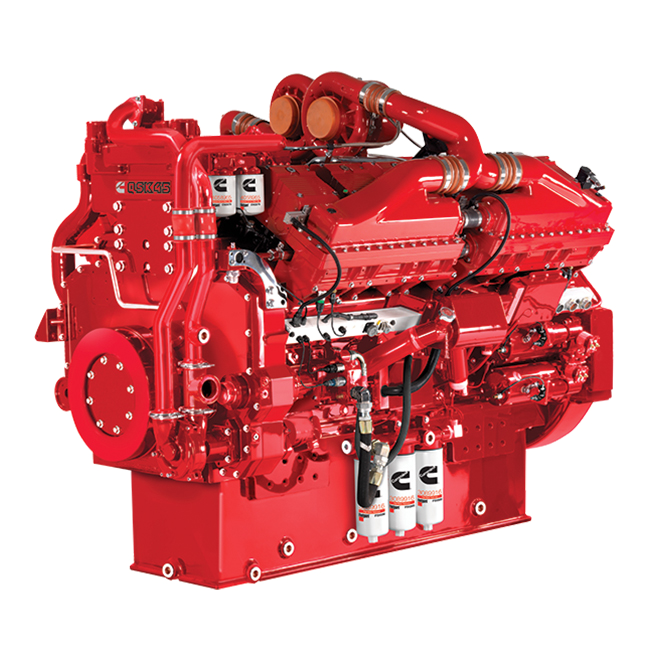

Diesel engines with electronic control and central switching-off impeller of cooling system provide high specific power and consequently high speed of dump truck when driving uphill, as well as high fuel efficiency.

To facilitate starting of the engine at low temperatures mining dump trucks are equipped with engine liquid preheater, which provides heating of diesel fuel and coolant at starting of the engine, which significantly increases engine service life and ensures reliable operation of the system in various climatic zones, including the Far North.

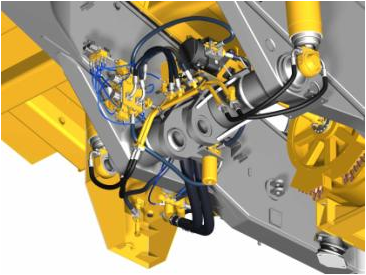

The integrated hydraulic system of the steering, braking and body hoist allows to unify the hydraulic drive and reduce the number of hydraulic units in the system design.

The use of adjustable pumps with an automatic unloading allows to reduce power losses in the drive and to provide oil cooling in various climatic zones without application of radiators.

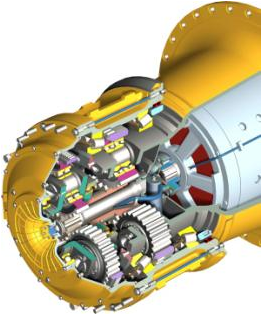

Bearing parts and gears of the motor-wheel reduction gear unit are made of the top-of-the-line alloy steels according to the most sophisticated technologies.

The applied kinematic scheme allows to transmit torque to the wheel hub simultaneously by the first and the second rows of the reduction gear unit and maximize the use of the space inside the wheel rim, reduces the actual loads in the reduction gear unit and provides its insreased service life.

Design solutions of the reduction gear unit eliminate the influence of deformations of gears and bearings of the unit that may occur during operation which makes it reliable and durable.

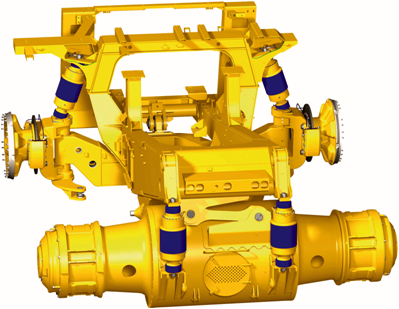

Pneumohydraulic suspension of mining dump truck with integrated hydraulic shock absorber in combination with the conventional system of the guiding apparatus provides high smoothness, performance, technical speed, lateral roll resistance and durability of dump truck components and comfortable working conditions for the operator.

The short wheelbase of the trucks ensures high maneuverability.

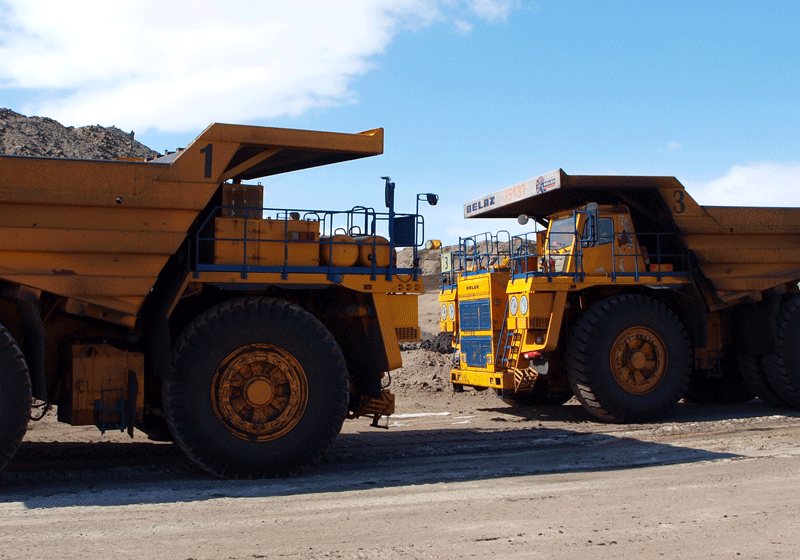

This series of the dump trucks features several modern, progressive, and innovative technical solutions for a number of units and systems.

The performance, reliability and operational attractiveness of the BELAZ-7513 series dump trucks is ensured through the use of highly efficient economical engines of the world's leading engine manufacturing companies, modern AC/AC or AC/DC electromechanical transmission, effective suspension, comfortable cab, powerful and reliable hydraulic system.

The manufactured equipment is equipped with additional units and systems that expand the functionality and improve operational attractiveness. There are standard and optional equipment sets. The set of equipment depends on climatic zone of operation: it can be northern or tropical.

Heating and air conditioning unit

Automatic centralized lubrication system

Loading and fuel control system

Telemetering tire inflation control system

Engine liquid preheater (except for tropical modification of dump trucks)

Video surveillance system

High-voltage line proximity alarm

Rock guards

Body bottom plate lining

Combined fire-fighting system with automatic control and subsystem in the rear axle

Refueling center

Clear comparison